In the bustling arena of warehouse management, optimising space is not solely a matter of organisation; it’s a strategic financial move. With the robust capabilities of NetSuite Warehouse Management System (WMS), businesses are positioned to transform their warehouse space utilisation into a cost-effective and efficient operation.

Before diving into optimisation strategies, it’s critical to understand how NetSuite WMS stands as a pivotal tool for financial stewardship in inventory management. By facilitating a data-driven warehouse design, the system ensures that every square foot of warehouse space is accounted for, translating to direct cost savings and enhanced inventory turnover rates.

The Analytics Edge: Cost-Efficiency through Data

NetSuite WMS analytics offer a magnified view of your warehouse operations, enabling you to identify cost-saving opportunities through improved warehouse space utilisation. Implementing these insights can significantly reduce inventory carrying costs and operational expenses, making warehouse analytics insights an indispensable asset for financial planners. Learn about implementing these insights in ‘Demand Forecasting with NetSuite WMS: Predict, Plan, and Prosper.’

Optimisation Techniques and Their Financial Impact

Through strategic warehouse layout optimisation, NetSuite WMS aids in the precise allocation of inventory, which is pivotal in optimising storage costs. Slotting optimisation and pick path optimisation are among the advanced techniques that not only streamline operations but also lower the cost of warehouse space waste by reducing unnecessary handling and movement.

Strategic Warehouse Layout Optimisation Techniques with NetSuite WMS

Maximising your warehouse’s financial efficiency hinges on a strategic approach to layout optimisation, leveraging the full suite of analytical tools within NetSuite WMS. Here’s how you can use NetSuite WMS analytics to revamp your warehouse layout:

1. Detailed Analysis with NetSuite WMS Analytics:

- Start by deploying NetSuite WMS analytics to gather comprehensive data about your current warehouse operations.

2. Employ Data-Driven Insights for Space Utilisation:

- With NetSuite’s granular insights, pinpoint under-utilised spaces and identify bottlenecks that can be alleviated, thereby improving your warehouse’s space utilisation and financial outcomes.

3. Optimisation of Pick Paths and Inventory Placement:

- Utilise the analytics to optimise pick paths, reducing the time and labour cost associated with order fulfilment.

- Apply insights to optimise inventory placement, ensuring that the most frequently accessed items are easily reachable, thereby reducing unnecessary movement and handling.

4. Measure and Adjust for Continuous Improvement:

- Continuously measure the impact of the changes you’ve made via NetSuite WMS analytics, focusing on financial metrics such as the reduction in carrying costs and improved order accuracy.

- Use this data to make further adjustments, ensuring your warehouse layout remains optimised for both space and cost-efficiency.

5. Responding to the Question:

- When optimising your warehouse layout, keep asking, “How can I optimise my warehouse layout using NetSuite WMS analytics?” This persistent inquiry will keep you aligned with continuous improvement and financial optimisation.

Now is the time to reevaluate your warehouse space efficiency and financial health with NetSuite WMS. Discover more about enhancing inventory accuracy in ‘The Power of Real-Time: Inventory Tracking with NetSuite WMS.’ Take the first step towards optimisation by scheduling a consultation with Jcurve today.

Measuring Financial Gains from Optimised Warehouse Space

Implementing NetSuite WMS space optimisation techniques directly influences the bottom line. We can measure the financial impact of these changes in various ways to ensure that every action taken towards optimisation is also a step towards greater financial health.

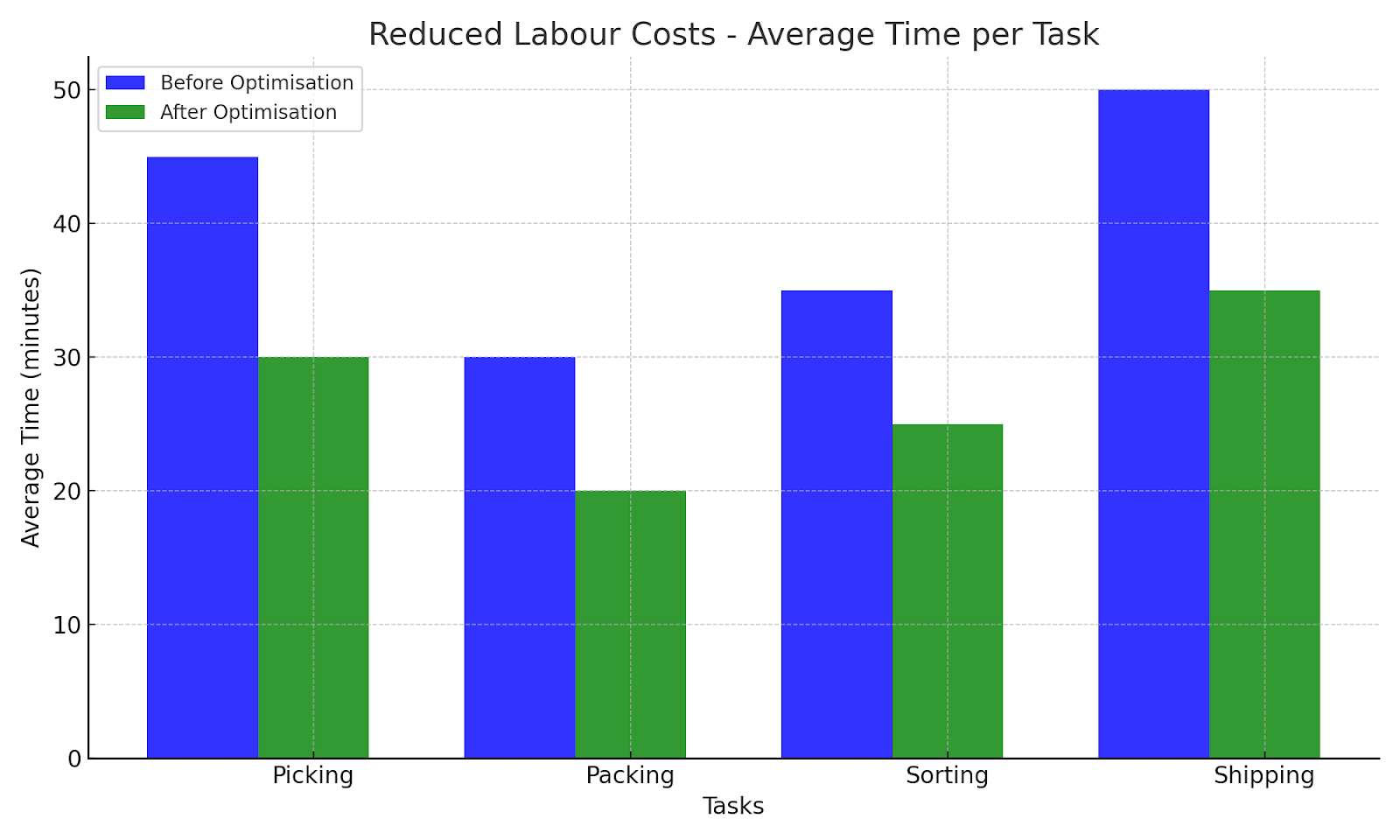

Reduced Labour Costs:

- Track the average time taken for picking and packing before and after optimisation. A reduction in time directly correlates to reduced labour costs.

- Monitor overtime hours; efficient space usage should decrease the need for additional labour hours.

Increased Inventory Accuracy:

- Measure the rate of order returns due to picking errors. A lower rate post-optimisation reflects higher accuracy and lower costs related to returns processing.

- Calculate inventory shrinkage rates before and after the changes. An improvement indicates better stock control and less financial loss from inventory mismanagement.

Enhanced Storage Capacity:

- Compare the amount of inventory held before and after optimisation. Increased capacity can defer the capital expenditure of warehouse expansion.

- Evaluate the utilisation of vertical space and its impact on the need for additional or external storage solutions.

Improved Inventory Turnover:

- Assess the inventory turnover ratio to see if there’s an increase post-optimisation, indicating more efficient stock movement and sales.

- Look at the holding cost reduction as inventory spends less time in storage, which ties up less working capital.

Decreased Facility Costs:

- Evaluate changes in utility costs due to more efficient space usage, potentially lowering electricity and heating costs.

- Examine the reduction in equipment wear and tear, which can result in lower maintenance and repair expenses.

ROI from System Implementations:

- Calculate the return on investment (ROI) of NetSuite WMS by comparing the costs saved over a period to the costs incurred in implementing the optimisation techniques.

- Consider the opportunity cost of space — savings from not needing to move to a larger facility or rent additional storage space.

Customer Satisfaction and Retention:

- Monitor customer feedback and repeat orders, as an optimised warehouse can lead to faster delivery times and better service, increasing customer loyalty and lifetime value.

- Assess any reduction in expedited shipping costs as a result of more efficient picking and processing.

Error Reduction and Waste Minimisation:

- Quantify the financial impact of reduced errors in inventory records, which can cause overstocking or stockouts, both of which are costly.

- Track the waste management costs, including disposal and recycling expenses; these should decrease with better inventory accuracy and less damaged goods.

The financial health of your warehouse is closely tied to how effectively you utilise its space. For a deeper dive into strategic space optimisation, read ‘Warehouse Management Tips to Boost Efficiency & Reduce Warehouse Costs.’ NetSuite WMS emerges not just as a space optimisation software but as a comprehensive tool for ensuring financial optimisation in warehouse operations.